new01bike

new01bike

The 1st 100% recycled 3D printed

polycarbonate bike frame.

polycarbonate bike frame.

New01bike is a more than a project, it’s a manifesto.

With this project, we wanted to elegantly, but loudly express the potential of recycled materials, additive and social interaction.

It’s time to recycle, to share, to invent and to recycle again, enjoying what modernity gives us, not just as individuals, but as intelligent custodians of this wonderful world and as proud stakeholders of this community.

Designed by INDEXLAB and manufactured with Gimac’s technology, New01bike was created to make a custom bike affordable, fast to customise and to produce, by using recyclable and recycled polymers.

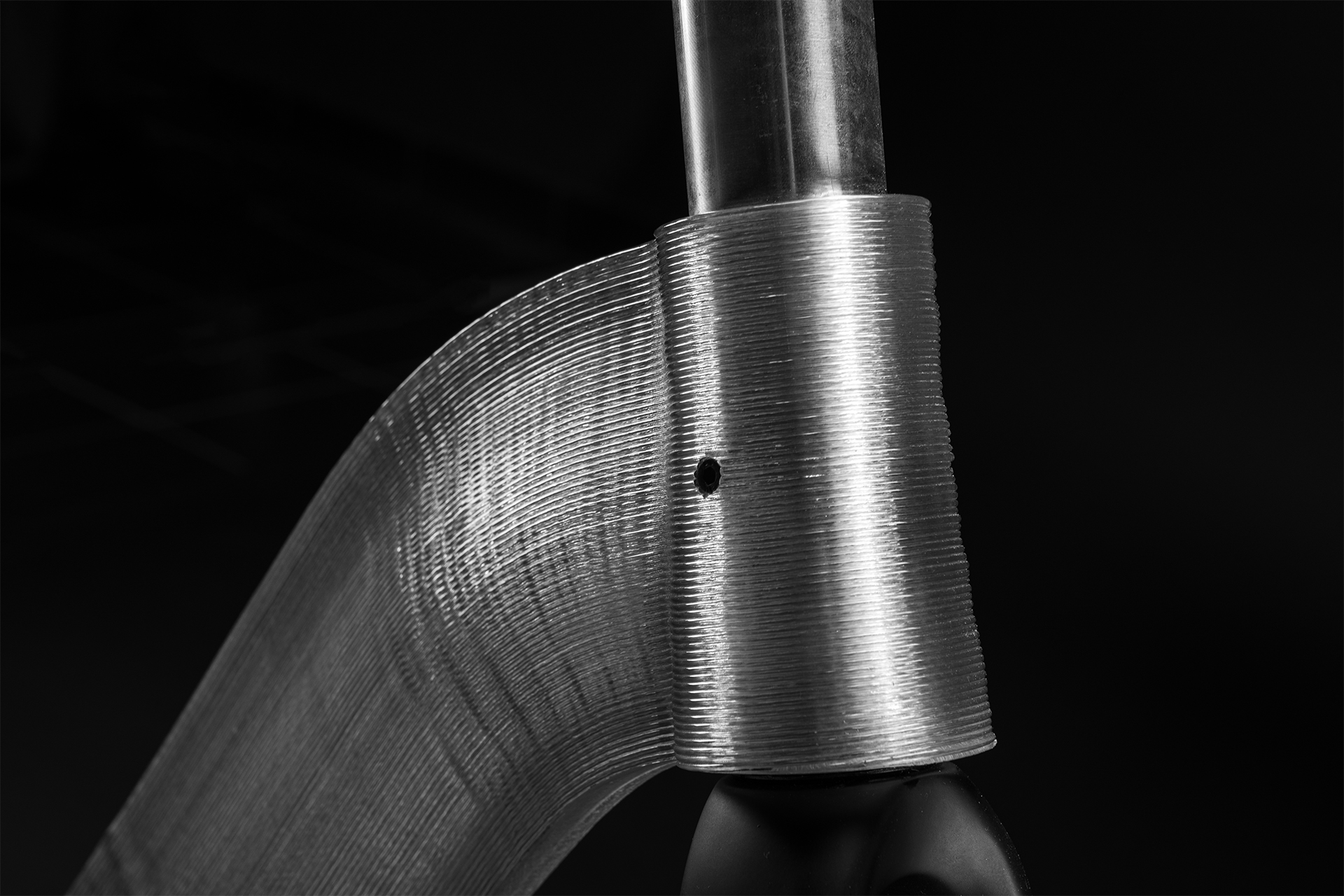

New01bike was developed in cooperation with INDEXLAB, a leading design and innovation research lab in Italy and GIMAC, a leader company in the realm of polymer extrusion and robotic additive molding (RAM). Employing technologies that involve robotic manufacturing and computational design processes, the New01bike’s first working prototype takes about eight hours to be manufactured from the ground up, from printing and milling to assembling.

The employment of additive manufacturing processes enables an essential transparent frame – weighing about eight kilograms – to be crafted out of what once could have been safety glasses, CDs, and DVDs.

It is precisely this dedicated algorithm that, through parametrization, further enables the scaling of the project to produce a holistic “design for all” product, enabling the control of every detail, movement, and aspect of the 3D printing and the milling process, to tailor the bike to every possible user; in other words, to skew off from mass serialization and embrace mass customization.

Currently on display at the Design Museum in Munich, represents the latest evolutionary link in the history of the bicycle.

New01bike is a more than a project, it’s a manifesto.

With this project, we wanted to elegantly, but loudly express the potential of recycled materials, additive and social interaction.

It’s time to recycle, to share, to invent and to recycle again, enjoying what modernity gives us, not just as individuals, but as intelligent custodians of this wonderful world and as proud stakeholders of this community.

Designed by INDEXLAB and manufactured with Gimac’s technology, New01bike was created to make a custom bike affordable, fast to customise and to produce, by using recyclable and recycled polymers.

New01bike was developed in cooperation with INDEXLAB, a leading design and innovation research lab in Italy and GIMAC, a leader company in the realm of polymer extrusion and robotic additive molding (RAM). Employing technologies that involve robotic manufacturing and computational design processes, the New01bike’s first working prototype takes about eight hours to be manufactured from the ground up, from printing and milling to assembling.

The employment of additive manufacturing processes enables an essential transparent frame – weighing about eight kilograms – to be crafted out of what once could have been safety glasses, CDs, and DVDs.

It is precisely this dedicated algorithm that, through parametrization, further enables the scaling of the project to produce a holistic “design for all” product, enabling the control of every detail, movement, and aspect of the 3D printing and the milling process, to tailor the bike to every possible user; in other words, to skew off from mass serialization and embrace mass customization.

New01bike represents the latest evolutionary link in the history of the bicycle.

It exemplifies how design, technology, and materials combine to create a contemporary product that is in line with the most advanced design and production techniques. New01bike is conceived in the form of an algorithm to be produced through a non-planar 3D printing process.

Personalization is in its DNA, allowing it to adapt to different sizes and aesthetic-functional features. The frame of New01bike is the first 100% recycled and recyclable polycarbonate frame.

Utilizing technologies that involve robotic manufacturing and computational design processes, the New01bike’s first working prototype takes approximately eight hours to manufacture from start to finish, including printing, milling, and assembly.